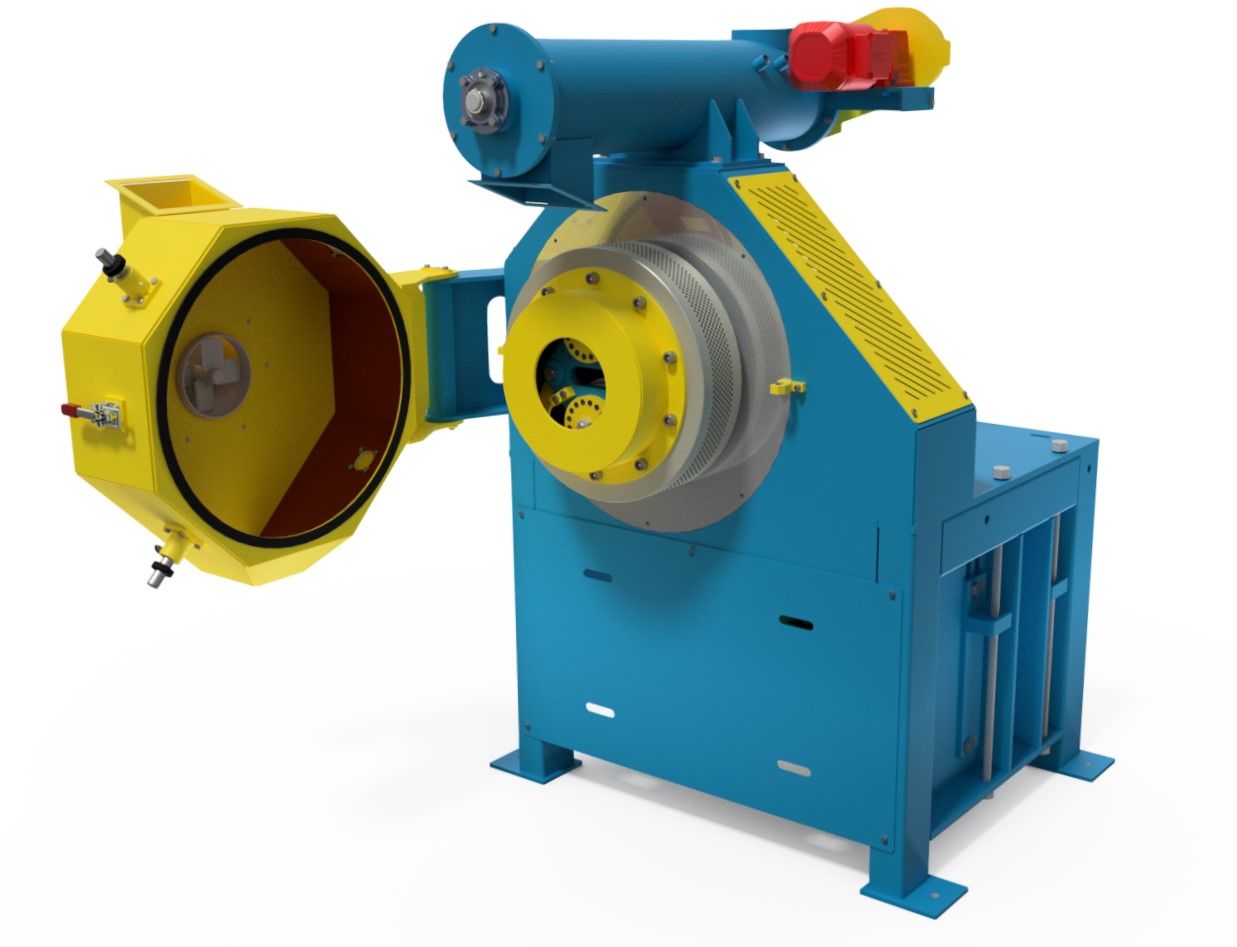

Turn Wood Waste into Fuel with Our Pellet Mills Made in Australia

McKEECO General Engineering has designed and manufactured a pellet mill tough enough to handle all wood products, even Australian Hardwood. The mill can process various materials into wood pellets suitable for various applications, from biomass fuel for renewable bioenergy to pet litter. Our pellet mills are designed and built in Lismore and are available for industries Australia-wide and overseas.

How the Pellet Mill Works

Our pellet mill utilises a six-step pelleting process:

- Fine grinding: Chippers/Shredders, Hammer Mills

- Surge Hopper and conditioning

- Pellet Production

- Cooling

- Sifting

- Packaging

The raw materials are finely ground during the first step using chippers, shredders, or hammer mills. This helps create a consistent size and texture for the pellets. Next, the ground material is placed in the surge hopper and conditioned to optimise moisture content for pelleting.

The pelleting process then begins, where the conditioned material is compressed and extruded through a die to form pellets. The newly formed pellets are then cooled, sifted, and packaged for distribution.

What Materials Can be Used in the Mill?

Our pellet mills can process a wide variety of materials, including:

- Discarded wood, including Australian hardwood

- Sawdust

- Wood chip and shavings

- Grain husks

- Fruit pips/stones

- Green waste, including grass

- Straw

- Agricultural by-products, such as bagasse and cotton trash

We developed our pellet mill to repurpose sawmilling residue, but we have found that many other types of wood and green products can be pelletised in the mill. Our pellets are suitable for many applications, from biomass fuel for renewable bioenergy to pet litter.

Contact us for more information on your pellet milling requirements.